|

A candidate for licensure as a teacher of manufacturing careers must complete at least a baccalaureate degree from a regionally accredited college or university and a preparation program under subpart 2 that must include the candidate’s demonstration of the knowledge and skills in items A to E

|

B.S. Industrial Technology Bemidji, MN M.S. Technology Education

St. Cloud State University Teaching Licensure Technology Education 9-12 MN PELSB (file folder 505683) Worked for E-Tech Inc. As an installer/welder, Project Lead, Installation Manager overseeing all Mechanical and Electrical installations. |

|

A. A teacher of manufacturing careers must demonstrate the knowledge and applications of academic subject matter required for proficiency in the following areas:

1) knowledge of math and science to manufacturing situations within specific manufacturing careers; 2) technical reading and writing in a manufacturing environment such as creating and interpreting graphs, charts, manuals, journals, and specifications; 3) problem solving in mathematical applications such as equations, formulas, and processes; and 4) applying manufacturing terminology for communication with co -workers, customers, and employers. |

Section A. |

|

B. A teacher of manufacturing careers must demonstrate knowledge and application of safety principles according to the rules and regulations of: 1) the Occupational Safety and Health Administration (OSHA);

2) the Environmental Protection Agency (EPA); and 3) the Material Safety Data Sheets (MSDS). |

Section B.Military training- Job Description skill level, administers first aid, performs preventitive Maintenance on equipment and vehicles. Operates wheeled vehicles to transport supplies, personel and equipment,Introduction to CISCO security design concept, Operational and organization Security 1 day.

|

|

C. A teacher of manufacturing careers must demonstrate knowledge and application of manufacturing careers by:

1) describing potential manufacturing careers; 2) describing the levels of education, licensing/certification requirements, employment opportunities, workplace environments, potential salaries, and career growth potential; and 3) utilizing personal occupational experiences to make manufacturing careers meaningful to the students. D. A teacher of manufacturing careers must demonstrate the knowledge and ability of the processes used to take a blueprint and manufacture a product from beginning to end using industry standards. These processes include:

1) general processes for manufacturing technology include: blueprint reading, layout techniques, hand tool processes/ identifications, measurement techniques, metallurgy, sawing techniques, abrasive processes, drilling techniques, quality control, jigs, fixtures and fasteners, accreditation/certification, laser processes, sheet metal processes, forging processes, and plastic technologies; 2) specific processes for machine trades including: precision measurement techniques, milling processes, turning processes, forming processes, precision grinding, numerical control, plastics/laminates processes, electrical discharge machining processes, stereo -lithography, tool and cutter grinding, computer aided drafting (CAD), computer aided machining (CAM), and geometric tolerancing; 3) specific processes for welding trades including: electrical polarities, electrode classifications, plasma arc cutting (ARC), oxy, fuel cutting (OFC), automatic cutting processes, gouging processes, oxy, acetylene welding (OAW), shielded metal arc welding (SMAW), gas metal arc welding (GMAW), flux core arc welding (FCAW), gas tungsten arc welding (GTAW), submerged arc welding (SAW), plasma arc welding (PAW), hard facing processes, and weld testing (nondestructive/destructive) |

Section C.Experience in the manufacturing industry.

E-Tech Inc. a material handling company that produced nearly all of it's own parts as well as electrical, mechanical engineering, programming, electrical and mechanical installation of products. 2005–2009 E-Tech Inc. Minneapolis, MN Installer/Installation Foreman May 2005 to September 2006 § Started travelling and installing systems through out the country § Ran my own installation crew after only 13 months on a 1 million + dollar installation § Became exceptional in layout, erection, welding and fabrication of steel, low voltage control wiring. § Completed jobs on time and with little or no supervision after only 6 months E-Tech INC Minneapolis, MN Installation Coordinator September 2006 to May 2007 § Established a link between installation, Engineering and Project Managers § Became efficient with AutoCAD and other software § Set up a training program for installation technicians and trained staff. E-Tech Inc Minneapolis, MN Installation Manager June 2007 to July 31, 2009 § Ran all aspects of the installations including scheduling, setting up flights, hotels, rental cars, seeking and arranging sub contractors, creating installation prints/packages, dealing with missing, incorrect parts, shipping these parts, striving to complete jobs on time and under budget. § Conducted employee reviews, hiring and firing of employees. § Trained mechanical installers in control wiring, after the elimination of the control wiring installers. Section D.Currently Melrose Area Public schools is partnered with Felling Trailers Inc. to provide a training work shop for high school students. Melrose has sent 6 students in the past two years. Also, in the past two years has had three certified welders at Felling Trailers Inc. and three students attending Alexandria Technical and Community College for Welding.

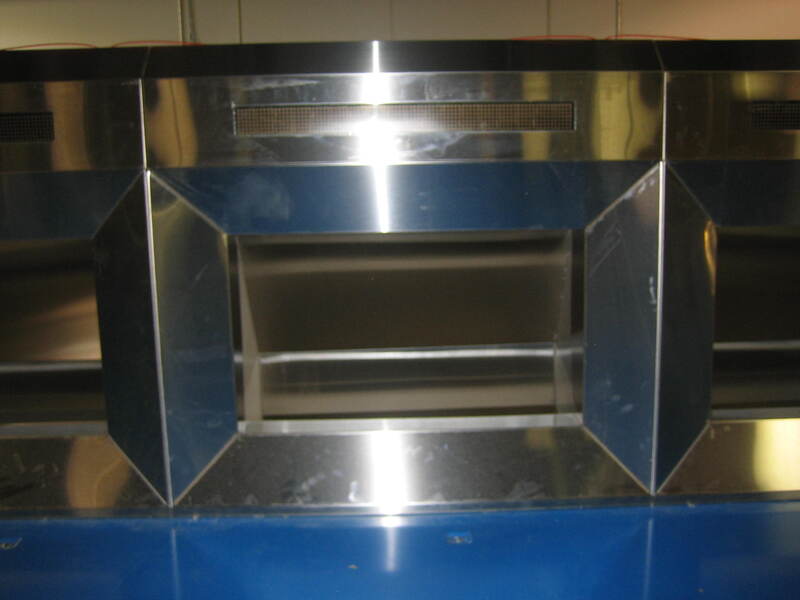

See images at bottom of page for examples of my first installation as a lead installer. |

|

E. A teacher of manufacturing careers must demonstrate knowledge and application of legal responsibilities and ethical practices in manufacturing including:

1) mortality and ethics and the relationship of each to manufacturing occupations, such as falsifying documents; 2) legal and policy issues impacting manufacturing industries, such as errors and omissions, negligence liabilities, and environmental issues and concerns; 3) understanding the importance of customer satisfaction, such as on time delivery and quality control; 4) employee protection documents, such as the Right to Know regulations; and 5) requirements for reporting and documentation of any activity that adversely affects the welfare of customers and fellow workers, such as incidence reports and hazardous material spills. |

Section E.A current member of CMMA and MTEEA.

|